Our Products

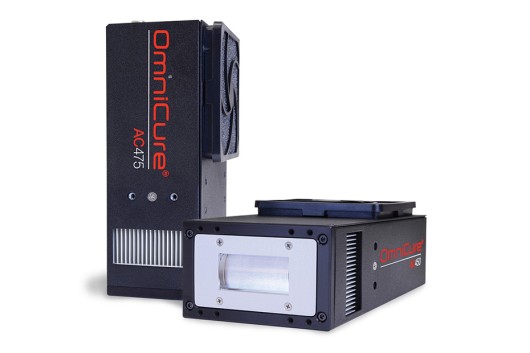

Jenton are distributors for Excelitas (Canada) in the UK and Ireland, a company at the forefront of UV LED curing products for the industrial and medical markets. Excelitas UV LED products are available as spot cure or linear sources with available wavelengths 365nm, 385nm, 395nm (UVA) and 265nm (UVC). They can all be fitted into Jenton UV curing conveyors and custom manufacturing jigs. They have innovative concentration optics and focusing lenses. Excelitas are experts in providing UV LED for engineering applications.

In addition, Jenton has worked for many years with Phoseon Inc. (USA) who present a very large range of UV LED arrays, with air and water cooling available, many of which have been specifically designed for OEM applications. Arrays can be large or small, linear or block and with a variety of power levels available. Phoseon are experts in providing UV LED for print applications.